Pultrusion in Unsaturated Polyester Resin

Time:

2023-07-22

Hello everyone! I would like to introduce to you the pultrusion process in unsaturated polyester resin.

| Pultrusion Resin | |

| Type | Description |

| 501A | Medium viscosity, excellent mechanical strength, medium HDT, suitable for rods and profiles and other products |

| 501B | Medium viscosity, good wettability, good mechanical properties, fast curing, high HDT, suitable for pultrusion tent poles and glass steel bars, etc. |

| 501C | Medium viscosity, good wettability, high mechanical strength, fast curing, suitable for ordinary rods and profiles, etc. |

| 501G | Medium viscosity, good wettability, high mechanical strength, fast curing, high cost performance, suitable for ordinary pultrusion products and profiles |

| 522A | Low viscosity, excellent heat resistance and mechanical properties, good wettability, fast curing, suitable for high corrosion resistance pultrusion products |

| 522B | Medium-active isophthalic unsaturated polyester resin, which has higher mechanical strength, better corrosion resistance, and better toughness than ordinary pultrusion resins, and is suitable for corrosion-resistant pultrusion products |

Hello everyone! I would like to introduce to you the pultrusion process in unsaturated polyester resin. Does the pultrusion process sound very high? In fact, it is the process of transforming unsaturated polyester resin into various shapes in a magical way.

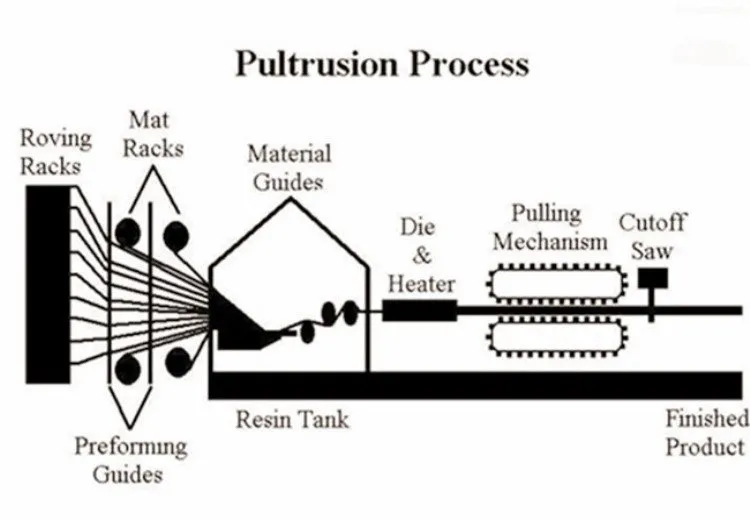

Step 1: Preparations

First of all, we need to prepare some materials, such as unsaturated polyester resin, glass fiber reinforced materials and so on. Of course, there is another very important tool, that is "pull".

Step 2: Mixing Materials

Next, we're going to mix the unsaturated polyester resin and fiberglass reinforcement together. This process is like cooking, the ingredients should be stirred evenly so that they are fully integrated.

Step 3: Pultrusion

Now, we are going to use that magic tool - "pull". We put the mixed material on the pulling machine, and then squeeze the material out of a small hole through the force of pulling. It's like making noodles, except that "resin noodles" are made here.

Step 4: Shaping

The extruded resin noodles will go through a series of processing, and finally become the shape we want. For example, we can bend them into tubes to make water pipes, or flatten them to make sheets.

Step 5: Curing

Finally, we have to wait for the resin noodles to cure. This process is like waiting for the dough to turn into a biscuit, it takes a certain amount of time. After the resin is cured, we can get a strong and durable product.

Through the pultrusion process of unsaturated polyester resin, we can manufacture a wide variety of products, which are widely used in construction, automobiles, ships and other fields. I hope today's introduction can bring you some joy, and at the same time understand the pultrusion process

Related news